Blackstone and the Post Office

(TL;DR: You can use the labels that are on your kits now, but if you’d like new ones, you can print one here.)

“I am FED UP,” said the customer on the phone. “Do you even have my sample? I mailed it a month ago.” I looked up his tracking number and he wasn’t exaggerating – he mailed it September 15, and we had just received it that day, October 15. Sound familiar?

Why is it taking so long for samples to arrive? And what are we doing about it? Read on, Blackstone fans. Have we got a story for you.

The Post Office makes some changes

“I think the post office isn’t charging us enough.” Ryan Stark, Blackstone’s president, and my brother and business partner, said to me one day last November after reconciling the checkbook. He’d noticed that for the last few months, the amount we were paying in postage had dropped significantly.

Stick with me, this is all going to tie together.

Last summer, just as we were all realizing the pandemic was not simply going to disappear, I learned the post office was ending their Merchandise Returns program. Because our samples came back to us on MR labels, we needed to create a new one, so I had my printer start working on it.

A major part of that process is getting approval from the USPS at various points along the way. And that’s where the process slowed…then slowed down some more…and then, like molasses on a winter sidewalk, came to a creeping halt.

We called USPS. How’s the label going? No reply. We emailed. How’s the label coming along? Nothing. Time passes. Months go by. Sometimes we’d get a reply – “We should have an answer for you soon!” But then…nada.

Back to the money

Meanwhile, the issue of not paying enough postage was still a problem. What do you do when you think the USPS isn’t charging your business enough? You call them – so I did.

I first contacted my local post office – the ones who deliver us samples every day, the ones who know who we are and what we do. “I think we’re not being charged enough,” I explained. “Nope, that’s not me,” she said. “They take care of that in Indianapolis now.” She gave me a number, so I called down to Indy. “Huh,” the Indy person said. “Let me look into it.”

Reader, you can see where this is going.

I got nowhere in November, so I called again in January. “Hey!” I said. “I still don’t think we’re getting charged enough!” “Hmmm” said the voice on the line. “Let me ask my supervisor about that.”

Time marches on. After calling and emailing various USPS representatives throughout February and March, I got fed up in April and sent an email blast to every single USPS contact I had, including the ones in Washington, D.C.

That one got some attention.

They started looking into what was going on, and to make a long story short, the issue culminated in a conference call with several USPS bigwigs. “Well,” said Bigwig #1, “you owe us (insert a huge amount of postage here. Nope, it was more than that).

It turns out that when the USPS stopped their Merchandise Returns program, our local post office stopped charging us for our incoming samples. We were still being charged for outgoing mail, but we hadn’t paid postage on incoming samples since the MR program ended in August.

After much gnashing of teeth and some heated words on my end (would they ever have caught the problem if I hadn’t kept after them? We’ll never know), we settled on a plan to pay the outstanding postage.

As part of this reconciliation, one of the USPS Bigwigs suggested we have samples returned to us in a Tyvek envelope, to help catch spills. Well, oil spills aren’t really the problem with getting samples delivered, but I tucked the idea away for the future.

Back to the labels

Meanwhile, the new label still had not been approved. And people still needed kits. While all this was going on, we continued to print and send out hundreds of thousands of old labels on kits. What choice did we have? Now those old Merchandise Return labels are now on kits that are sitting in garages, hangars, and marinas all over the country.

So when did we get it resolved? We officially started printing our new, USPS-approved labels more than a year after the old label was officially discontinued. The thing is, the post office reassured me that it would be fine to continue to use our old label – we would just have to pay more when people returned them.

Which is fine. Fine, fine, fine. Except, for some post offices, it’s not so fine. Most of those old, Merchandise Return-labeled kits get here no problem. But occasionally, a post office will hold on to it and not deliver it because it’s the old label, even though they said we could keep using them.

At this point, there’s nothing we can do about the thousands of old labels that are in circulation except try and get the word out. So that’s why you’re reading this. If you have old labels on your kits (they say Merchandise Return right on them), click here to ask for new ones. We really do want to receive your samples. And we don’t want you to have to wait for a month to get your results.

But wait, there’s more!

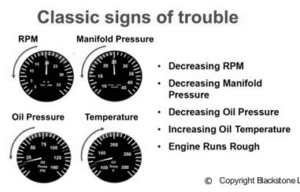

So while all of that was going on, Travis – a long-time Senior Analyst-turned-coder – had an idea. “What if,” he said to me one day, “we do a test to see if putting samples in a Tyvek envelope helps with the return postage time?” Because although oil spills aren’t a significant problem, it does seem to be a problem that the mailer is 1) small, and 2) clearly headed for a laboratory. Putting the oil into a Tyvek envelope might solve both issues. So we started a test – for one month, we sent all outgoing kits with a labeled Tyvek envelope for returning the sample to Blackstone.

The results were immediate and striking: this was a winner. We didn’t even run the test for the full month. The data Travis put together showed that return times were cut in HALF (from an average of 8.74 to 3.48 days) when samples came back to us in the Tyvek envelope. (See the sidebar.) We stopped the test and immediately started including Tyvek envelopes with each kit order, for return samples.

USPS supporters

Despite the problems, we are proud supporters of the United States Postal Service. No other carrier offers service to every single part of the US, no matter how remote. Lots of people don’t have access to UPS or FedEx, though if you want to use them to send in your samples, that’s absolutely fine.

The changes we’ve made to our label and the return package are already paying off in getting samples to us in a timely fashion. If you need new return envelopes and labels for your kits, let us know – we’re happy to send them out!

______________________________________

Update! The Post office has discontinued their First Class Return labels (my new mantra: change is good…change is good). We are now using Ground Advantage labels. All the same things in this article still apply. You can use the First Class return labels, but your sample will arrive faster with a Ground Advantage label. You can print one off right here.