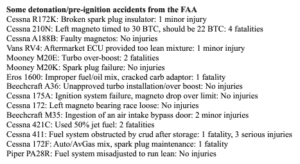

Pre-Ignition and Detonation

The information (and harrowing pictures!) that follows is reprinted courtesy of the FAA.

Pre-ignition. Detonation. Both can be deadly. But what’s the difference? And how can you avoid them?

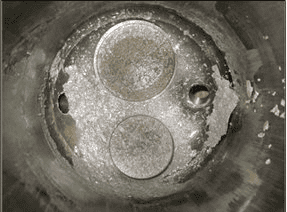

This engine is from a Beech S35 Bonanza’s fatal accident. The #6 piston was eroded and began to melt. The rings and piston skirt were compromised by thermal expansion and metal transfer. Note the deep pitting and erosion of the piston face. This caused combustion gases to bleed into and over-pressurized the crankcase, forcing engine oil out the breather. The connecting rods then failed due to the lack of lubrication and smashed holes in the crank case, causing loss of power and engine failure.

Normal combustion vs. pre-ignition

Normal combustion is an orderly, progressive burning of the fuel-air mixture in the cylinders. The gasses within the cylinders are ignited from the top. The flame then travels down in an organized way. This combustive force, equally applied to the piston in a stable manner, pushes the piston down. The downward motion of the piston is then mechanically transferred to the propeller. This makes pilots very happy.

In a pre-ignition event, combustion is abnormal. It happens when the air-fuel mix ignites before the spark plug fires, while the piston is still moving up in the compression cycle. The ignition can be caused by a cracked spark plug tip, carbon or lead deposits in the combustion chamber, a burned exhaust valve, an ignition system fault, or anything that can act as a glow plug to ignite the charge prematurely.

When this happens the engine works against itself. The piston compresses and at the same time the hot gas expands. This puts tremendous mechanical stress on the engine and transfers a great deal of heat into the aluminum piston face damaging the piston. Engine failure can happen in minutes.

Detonation

As the name suggests, detonation is an explosion of the fuel-air mixture inside the cylinder. It occurs after the compression stroke near or after top dead center. During detonation, the fuel/air charge (or pockets within the charge) explodes rather than burning smoothly. Because of this explosion, the charge exerts a much higher force on the piston and cylinder, leading to increased noise, vibration, and excessive cylinder head temperatures.

The violence of detonation also causes a reduction in power. Mild detonation may increase engine wear, though some engines can operate with mild detonation. However, severe detonation can cause engine failure in minutes. Because of the noise that it makes, detonation is called “engine knock” or “pinging” in cars.

High heat is detrimental to piston engine operation. Its cumulative effects can lead to piston, ring, and cylinder head failure and place thermal stress on other operating components. Excessive cylinder head temperatures can lead to detonation, which in turn can cause catastrophic engine failure. Turbocharged engines are especially heat sensitive.

Some causes of detonation include:

- improper ignition timing

- high inlet air temperature

- engine overheating

- oil in the combustion chamber

- carbon build-up in the combustion chamber

A combination of high manifold pressure and low rpm creates a very high engine load, which can also cause detonation. In order to avoid these situations:

- When increasing power, increase the rpm first and then the manifold pressure

- When decreasing power, decrease the manifold pressure first and then decrease the rpm

Pre-ignition and detonation results

The explosion of pre-ignition and detonation is like hitting the piston with a sledge hammer. The automotive term for the sound it makes is “ping” (something pilots cannot hear in aircraft). The ping sound is the entire engine resonating at 6400 hertz. It sounds like a ping, but it is an explosion with enough power to make the engine resound like a gong.

Both pre-ignition and detonation put tremendous mechanical stress on the engine and transfer a great deal of heat into the piston deck. This can cause the piston to melt (EGT is 1600 degrees; aluminum pistons melt at 1200 degrees). The force of these explosions can knock holes in pistons, bend connecting rods, overcome the lubrication film in the rod bearings, and hammer the babbitt out of rod bearings. Engine failure can happen in minutes.

The bent connecting rod at the start of the article is a good example of the damage pre-ignition and detonation can do.

These cylinder #2 spark plugs are packed with melted piston material.

Here’s what happens

This is a cylinder head showing signs of pre-ignition or detonation.

The carbon coating that normally lines the head dome is knocked off. There is melted piston material in the head and the cylinder sleeve is scored by the overheated piston.

This is the same piston , but note that the piston deck is eroded.

The rings are broken. The piston skirt is scuffed from rubbing on the cylinder wall. A piston in this condition allows combustion gases into the crank case. This over-pressurizes the crankcase and blows engine oil out of the crank case breather — all of the engine oil, in minutes.

Soon after the engine oil departs the connecting rods try to make a break for it, resulting in giant holes in the crank case.

How do I detect pre-ignition?

A rough-running engine can be the first sign of pre-ignition or detonation. High EGTs or CHTs can be a sign of a problem so be sure to keep an eye on that if you can.

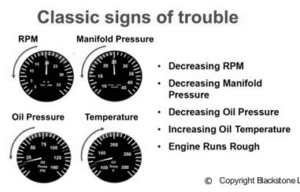

Below are common indications of detonation. You should have increasing oil temperature, not pressure. The top left gauge is RPM. The top right is manifold pressure.

What do I do when it happens?

Since excessive heat can be so damaging, your main priority is to cool the engine:

- Reduce power

- Increase airspeed

- Enrich the fuel mix

- Open the cowl flaps.

- Land immediately!

Preventing Pre-ignition

- Do not take off unless the run-up is perfect

- Maintain the ignition system

- Pay attention to cylinder compression tests

- Use the proper heat range spark plugs

- Make sure cooling baffles are in good repair

Preventing Detonation

- Lean the engine per the flight manual

- Keep engine load to a minimum

- Do not over boost

- Use only the recommended fuel grade

- Make sure engine timing is properly set

- Make sure cooling baffles are in good repair

- Be wary on hot, dry days

- If in doubt, run rich