The Lower Unit Blues

I wouldn’t consider myself a nautical man, though growing up fairly close to a lot of really nice lakes, I was able to go fishing, tubing, and water skiing every now and then. These are all things I still enjoy though this type of hobby generally requires a boat. My grandfather gave me a fishing boat many years ago and while that doesn’t need much maintenance, I do use my step-mother Kathy’s boat once or twice a summer and that’s a different story.

The boat & its lower unit

The boat is a 1994 Starcraft 1700 with a 90 HP Mercury 2-stroke engine. It’s large enough to carry six people comfortably and pull a tube around the lake. She bought the boat used in 2016 and it had obviously not seen a whole lot use or maintenance in the preceding years, so I decided to help out with what little maintenance I could, which basically involved changing the oil in the lower unit.

The boat is a 1994 Starcraft 1700 with a 90 HP Mercury 2-stroke engine. It’s large enough to carry six people comfortably and pull a tube around the lake. She bought the boat used in 2016 and it had obviously not seen a whole lot use or maintenance in the preceding years, so I decided to help out with what little maintenance I could, which basically involved changing the oil in the lower unit.

Now for those of you who are even less nautical than me, the lower unit is a gear box that transmits power from the engine to the propeller. Technically, it can be called a transmission, but that doesn’t really apply because it only has two gears—forward and reverse—and there isn’t any sort of complicated clutching system involved to change the gears. It’s basically a gear box, which tends to be extremely reliable and would have a super long life if it wasn’t for the environment in which it has to operate—underwater.

The water blues

As you might have guessed, water contamination is a major problem with these units and when I changed the oil in Kathy’s boat, I could tell that water was getting in.

Now, you don’t have to have worked at an oil lab for 20+ years to know what serious water contamination looks like. Think milkshake, with the main color being whatever the color of the oil was to start with. When an oil with red dye gets water in it, it tends to look like strawberry milkshake. If the oil starts out blue, you end up with a blueberry milkshake. Start with brown oil and you get chocolate.

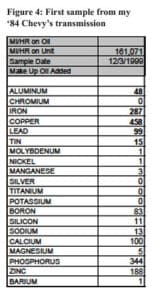

So the very first time I changed it, I grabbed a sample as the oil was draining out to see how bad the water contamination was (see Figure 1).

Figure 1: Not good

Here at the lab, even though an oil might obviously have water in it, we don’t just use the color to make that call; we use an actual ASTM method to identify water. The test is called the “crackle test.”

For that, you drop a small amount of oil onto something hot (400°F) like a brass cup, and if the oil sizzles/crackles, then yes you have water. (We get the percentage from the insolubles test but that’s another matter.) If you are crunched for time and can’t send your oil in to us, you can actually do this test at home in your kitchen using an old pan. Just don’t cook up a batch of eggs on it afterwards.

The good thing about lower units is, if you keep the oil changed and no water is getting in, they will last for a very long time. And if water is getting in, frequent oil changes will keep any damage to a minimum. However, if you neglect one that does have water leaking in, the water will cause the steel parts to rust and that will allow for all kinds of bad things to happen. In my situation, I knew the lower unit in Kathy’s boat was letting water in and that something should have been done about it, but life got in the way.

Live & learn (and hopefully don’t wreck)

So this year, when I went to try to put it in the lake I got quite the surprise when I found it the motor would not shift out of forward. Of course, I didn’t know this until I was trying to back the boat away from the boat trailer at the ramp. Needless to say, I was very confused as to why the boat was going forward when I had it in reverse, and Kathy was even more confused (and profane) when she thought the boat was going to end up in the bed of her truck. I did start the engine prior to heading to the lake and it was running like a champ. I just didn’t think to check to see if the motor would go into reverse, or even shift at all. Live and learn.

So now the lower unit is in a partial state of disassembly in my garage, and let me tell you—nothing is a sadder sight in the middle of boating season. I find myself struggling with shame and regret about not having changed oil in it sooner, or better yet, just fixed the seal that was letting water in in the first place. My only hope is that you don’t let the same thing happen to you. Change that lower unit oil and sleep easy at night. Meanwhile, I’ll be learning the real meaning of the word boat – Bust Out Another Thousand!

It was always a bit of a mystery as to where lead came from in that type of transmission and it turns out, it’s a bearing metal, just like what used to be common in engines.

It was always a bit of a mystery as to where lead came from in that type of transmission and it turns out, it’s a bearing metal, just like what used to be common in engines.

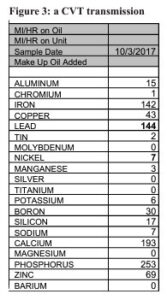

Again, most of these oils are light in viscosity (10W) but they have a unique additive package, and they also tend to be dyed blue or green to differentiate them from the typical red ATF that many transmissions run. Unfortunately, we see a lot of samples from CVT transmissions where the wrong oil has been used. This causes the units to burn up because the belt driving the cones relies on the oil’s additives to maintain the correct friction.

Again, most of these oils are light in viscosity (10W) but they have a unique additive package, and they also tend to be dyed blue or green to differentiate them from the typical red ATF that many transmissions run. Unfortunately, we see a lot of samples from CVT transmissions where the wrong oil has been used. This causes the units to burn up because the belt driving the cones relies on the oil’s additives to maintain the correct friction.